1) milling time

研磨时间

1.

The Influence of Milling Time on Properities of Aluminum Titanate Ceramic Slip and Fired-Product;

研磨时间对钛酸铝陶瓷泥浆及制品性能的影响

2.

This paper discusses the action of dispersant in cathodic electrodeposition coatings, analyzes the influence of dispersant on milling time, storage stability and colorant viscosity of coatings, concluding that 0.

讨论了分散剂在阴极电泳涂料中的作用,分析了其对研磨时间、贮存稳定性及色浆黏度等涂料性能的影响。

2) grinding shop

研磨车间

3) milling time

球磨时间

1.

Effect of milling time on the properties for low-temperature sintering of BaO-TiO_2-Nb_2O_5 microwave ceramics;

球磨时间对低温烧结BaO-TiO_2-Nb_2O_5微波陶瓷性能的影响

2.

The effect of different milling time on performance of W-Cu composites was investigated.

研究了不同球磨时间对钨铜复合材料性能的影响。

3.

The effects of milling conditions such as milling time,ball/powder weight ratio, dry milling and wet milling etc.

讨论了球磨时间、球料比、干、湿磨等因素对颗粒细化的影响。

4) wear time

磨损时间

1.

The dry sliding friction and wear characteristics of die casting magnesium alloy AZ91D,which was in as-cast,T4 heat treatment and T6 heat treatment state, were studied at different load and wear times by using an MM-200 abrasion tester.

采用MM-200型磨损试验机,研究了干滑动摩擦条件下载荷和磨损时间对液态压铸成形镁合金AZ91D摩擦磨损性能的影响,借助扫描电镜探讨了材料的磨损机理。

2.

The effects of load and wear time on the wear characteristics of magnesium alloy AZ31 were investigated in the dry sliding condition in the load range of 25N to 100N.

结果表明:合金的磨损质量损失在不同的载荷下均随磨损时间的增加而呈线性增加,载荷增加使磨损失重增加更显著。

5) ball-milling time

球磨时间

1.

The influence of ball-milling time on amorphous character was studied and the magnetic permeabilities under different frequencies of the pressed samples were measured.

研究了球磨时间对样品非晶化程度的影响 ,并测量了这些样品压结体的高频特性 。

6) time fpr grinding mine

磨矿时间

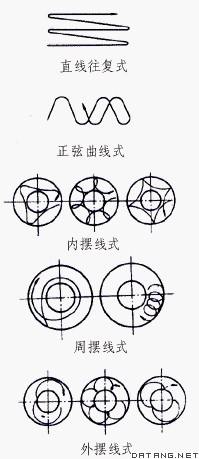

补充资料:研磨

| 研磨 lapping 利用涂敷或压嵌在研具上的磨料颗粒(研磨剂),通过研具与工件在一定压力下的相对运动对加工表面进行的精整加工。工件在研磨前要经过精磨等预加工,所留研磨余量一般为0.005~0.03毫米 。研磨后加工精度可达IT5~01,表面粗糙度可达0.63~0.01微米 。研磨可用于加工金属和非金属材料的多种表面,如平面、圆柱面、圆锥面、螺纹、齿面、球面等。单件小批量生产时用手工研磨,批量较大时用机械研磨。研具的硬度应比工件低一些,耐磨性要好,常用材料有灰铸铁、软钢、黄铜、紫铜等。研磨剂为磨料和油脂等调和而成的混合物,有液态、膏状和固态3种。为了减少切削热,研磨一般在低压、低速条件下进行。粗研时压力小于0.3兆帕 ,速度为20~120米/分;精研时压力为0.03~0.05兆帕,速度为10~30米/分。两个相配的工件,可以配研,两者互为研具,如阀座与阀芯,柱塞与柱塞套等。配研后可以达到很好的气、液密封配合。配研偶件只能成对使用,不具互换性。

|

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条