1) bevel gear drive

圆锥齿轮传动

1.

By use of two stage fuzzy comprehensive evaluation method of fuzzy dissertation, many complex influence factors in design of straight bevel gear drive are described and treatmented quantitatively, and the mathematical model of the fuzzy optimization design on minimizing volume is established and the optimal solution is found.

运用模糊论中二级模糊综合评判法,对直齿圆锥齿轮传动设计中诸影响因素的 模糊性进行了定量描述和处理,建立了以体积最小为目标的模糊优化设计的数学模型 并获得了最优解。

2) conus medullaris

圆锥

1.

Aim: To study the diagnosis and treatment of ependymoma in conus medullaris and cauda equins.

目的:探讨圆锥马尾部室管膜瘤的诊断及手术治疗特点。

2.

Objective To explore the clinical features and surgical findings of cauda equina and conus medullaris tumors.

①目的 探讨马尾圆锥肿瘤的临床及手术特点。

3) cone

圆锥

1.

A way of calculating the intersecting line of cylinder and cone with the aid of supplementary plane;

借助特定辅助平面求圆柱圆锥相贯线的方法

2.

Diagraming the characteristic points on the intersection lines between a sphere and a cone by means of the method of anxiliary sphere;

用辅助球面法求圆球和圆锥相贯线上特殊点

4) circular cone

圆锥

1.

Solution of obliquely intersection-line of cylinder and circular cone;

圆柱与圆锥偏斜交相贯线求法的研究

2.

The Spreading Picture Drawing of the Cylinder and Circular Cone Intersected in the Axial;

相交圆柱与圆锥表面展开图的计算机绘制

3.

The spherical method and auxiliary plane method are usually apply in making up the intersection line, while cylinder and circular cone intersect each other diagonally.

求作圆柱面与圆锥面轴线斜交时的相贯线 ,通常用的作图方法是球面法或辅助平面法。

5) tapered roller

圆锥滚子

1.

Discussion on machining technology for spherical fiducial surface of tapered roller;

圆锥滚子球基面加工工艺的探讨

2.

Study of generatrix shape of tapered roller processed with centerless grinding;

圆锥滚子无心磨削母线形状的探讨

3.

Improvement of regulation wheel guiding surface during tapered rollers outer surface grinding;

圆锥滚子外径表面磨削时导轮制导面的改进

6) taper ferrule

圆锥套圈

1.

Taking the cold rolling with the series of 2BD for ISO355 taper ferrule as the example,the method of the pair closed type rolling was used to reduce the spread of the product and to obtain a good surface.

以ISO355系列2BD圆锥套圈冷辗扩为例,采用成对闭式辗扩的方式,以达到减小成品宽展和形成良好端面的目的。

参考词条

补充资料:传动:摆线齿轮传动

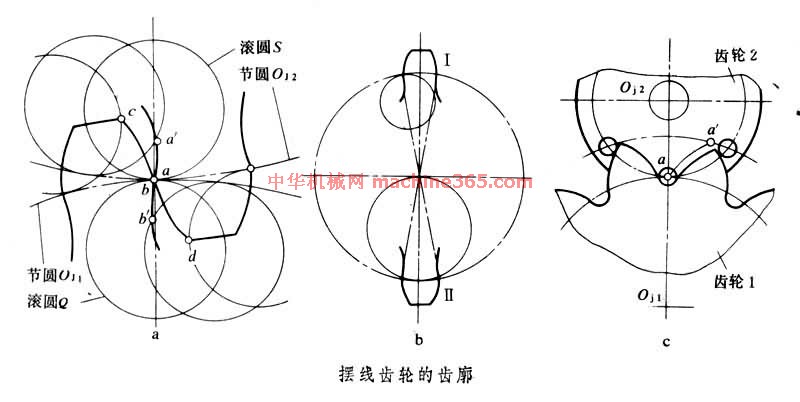

由一对摆线齿轮组成的齿轮传动。摆线齿轮的齿廓由内摆线或外摆线组成 (图中a 摆线齿轮的齿廓 )。滚圆S 在节圆Oj1外面滚动形成齿顶曲线bc ﹐在节圆Oj2内面滚动形成齿根曲线aa'﹔同样﹐滚圆Q 在Oj1内面滚动形成齿根曲线bb'﹐在Oj2外面滚动形成齿顶曲线ad。这样的轮齿接触传动相当於一对大小为Oj1和Oj2的摩擦轮互相滚动。摆线齿轮传动大多用於鐘錶和某些仪器﹐与一般齿轮传动相比﹐它的特点是﹕(1)传动时一对齿廓中凹的内摆线与凸的外摆线嚙合﹐因而接触应力小﹐磨损均匀﹔(2)齿廓的重合度较大﹐有利於弯曲强度的改善﹔(3)无根切现象﹐最少齿数不受限制﹐故结构紧凑﹐也可得到较大的传动比﹔(4)对嚙合齿轮的中心距要求较高﹐若不能保证轮齿正确嚙合﹐会影响定传动比传动﹔(5)这种传动的嚙合线是圆弧的一部分﹐嚙合角是变化的﹐故轮齿承受的是交变作用力﹐影响传动平稳性﹔(6)摆线齿轮的製造精度要求较高。

摆线齿轮传动分内外嚙合和齿条嚙合两种。齿条的齿顶和齿根都是滚圆在直线上滚成的摆线。这种传动还有一些变形齿廓 (图中b 摆线齿轮的齿廓 )。滚圆尺寸对齿根曲线有影响。齿廓Ⅰ的滚圆小﹐齿根部两侧曲线外伸﹔齿廓Ⅱ的滚圆直径恰等於节圆半径﹐内摆线变成一条节圆的半径线。如果再用圆弧代替齿顶的外摆线﹐轮齿即变成圆和直线的组合﹐加工就很方便﹐可用成形铣刀铣削或用衝压等方法製造。针轮传动(图中c 摆线齿轮的齿廓 )的节圆Oj2同时作为齿轮1的滚圆﹐另一滚圆半径为零。当Oj1在Oj2上滚动时﹐圆周上一点a在齿轮 1上画外摆线﹐但由於轮齿要传递运动和力﹐a点要用圆销来代替。这时aa'只是齿轮 1的理论齿廓﹐它的实际齿廓是圆销中心在aa'上运动时所形成的一条等距曲线。如果节圆Oj2的半径变为无穷大﹐针轮变为带有圆柱轮齿的齿条﹐这时齿轮1的齿廓便变为渐开线。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。