1) internal gear with small teeth difference

少齿差齿轮副

2) Leess tines

少齿

3) small tooth number difference

少齿差

1.

Application of double crank-link and small tooth number difference planetary gear reducer in cranes and elevators;

双曲柄连杆少齿差行星减速器在起重机械和电梯的应用

2.

Inquires into the EHL calculation for involutes planetary gear drive with small tooth number difference and its relative formulas are derived.

探讨了渐开线少齿差行星传动的弹性流体动力润滑计算,并推导出相应的计算公式以及分析了该传动的润滑状态,为渐开线少齿差行星传动的耐磨损设计提供了必要的理论依据。

3.

The researches of ring-plate gear reducer with small tooth number difference were re- viewed in several aspects such as load state analysis,load capacity,balance and vibration reduction, transmission efficiency and serialization design.

从受力分析、承载能力、平衡减振、传动效率和系列设计等方面,对少齿差环板式减速器的研究现状进行了评述。

4) few teeth difference

少齿差

1.

Study on the new inner planar moving spur gear typed epicyclic gear transmission with few teeth difference;

外齿轮内平动式新型少齿差行星传动的研究

2.

Finite element analysis of few teeth difference reducer inner meshing gears;

少齿差减速机内啮合齿轮的有限元分析

3.

The manufacturing method of some important transmitting parts of the bevel gear planetary re ducer with few teeth difference in inclined plate is studied, including the manufacturing technology of the internal bevel gear pairs, input shaft-inclined plate, inclined axle and the assembly and test technology.

对斜盘式锥齿少齿差行星减速器的一些重要传动元件的制造方案进行了系统研究和论证。

5) The least gears

最少齿数

1.

Analysis on the least gears in Gear Mechanism;

齿轮机构的最少齿数分析

6) less tooth difference

少齿差

1.

Establishment of optimized mathematic model for less tooth differenced planetary transmission mechanism with biasing crankshaft;

偏曲轴少齿差行星传动机构优化数学模型的建立

参考词条

少齿差行星传动

无根切最少齿数

少齿数齿轮机构

少齿数齿轮副

少齿差减速器

曲柄少齿差传动

渐开线少齿差

少齿差行星齿轮

少齿差内啮合

小模数、少齿数齿轮

渐开线少齿差行星传动

推广施用

花粉及其提取物

补充资料:传动:少齿差行星齿轮传动

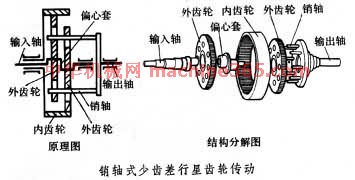

由一对齿数相差很少的内嚙合齿轮和输出机构组成的行星齿轮传动。通常齿数差为1~4。外齿轮通过轴承和偏心套装在减速器的输入轴上(见图 销轴式少齿差行星齿轮传动  )。为了平衡部分惯性力和提高承载能力﹐通常採用两个外齿轮﹐偏心套上有两个偏心并互成180°。内齿轮大多固定不动。输出机构将外齿轮的转动通过销轴传到输出轴上﹐并保持它的角速度不变。常用的输出机构有销轴式和浮动盘式等。渐开线少齿差单级传动一般採取的传动比为20~100以上﹐效率为0.8~0.9。它的齿轮可用一般齿轮机床加工。如外齿轮的齿数为Z ﹐内齿轮的齿数为Z b﹐则内齿轮固定时﹐输入轴和输出轴的传动比b=-Z /(Z b-Z )﹔输出轴(F )不动时﹐输入轴和内齿轮的传动比=Z b/(Z b-Z )。内﹑外齿轮的齿数差越少﹐每级传动得到的传动比越大﹐但齿数差少到一定程度时﹐例如採用压力角为20°的标準渐开线齿轮﹐当内齿轮数少於180﹑齿数差少於5~7时﹐内嚙合齿轮就会產生齿形重叠干涉。解决的办法是採用短齿并进行适当的变位。

)。为了平衡部分惯性力和提高承载能力﹐通常採用两个外齿轮﹐偏心套上有两个偏心并互成180°。内齿轮大多固定不动。输出机构将外齿轮的转动通过销轴传到输出轴上﹐并保持它的角速度不变。常用的输出机构有销轴式和浮动盘式等。渐开线少齿差单级传动一般採取的传动比为20~100以上﹐效率为0.8~0.9。它的齿轮可用一般齿轮机床加工。如外齿轮的齿数为Z ﹐内齿轮的齿数为Z b﹐则内齿轮固定时﹐输入轴和输出轴的传动比b=-Z /(Z b-Z )﹔输出轴(F )不动时﹐输入轴和内齿轮的传动比=Z b/(Z b-Z )。内﹑外齿轮的齿数差越少﹐每级传动得到的传动比越大﹐但齿数差少到一定程度时﹐例如採用压力角为20°的标準渐开线齿轮﹐当内齿轮数少於180﹑齿数差少於5~7时﹐内嚙合齿轮就会產生齿形重叠干涉。解决的办法是採用短齿并进行适当的变位。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。