1) friction/wear

摩擦/磨损

2) frictional wear

摩擦磨损

1.

Locomotive and rolling stock wheel/rail frictional wear and energy-saving and consumption-reducing

铁道机车车辆轮轨的摩擦磨损与节能降耗

2.

The frictional wear,electric property and microscopic structure were investigated by a MG-2000 high temperature and speed friction wear testing machine,SX1934(SZ-82)four-.

采用MG-2000型高速高温摩擦磨损试验机,SX1934(SZ-82)数字式四探针测试仪,XJL-03型金相显微镜,JSM-6700F扫描电镜等仪器测试并分析了其热摩擦磨损、电性能及显微组织。

3.

The effect of different sintering temperature on the microstructure,density and frictional wear property of the Fe-based powder metallurgy(P/M)brake materials of aircraft was studied.

研究了不同烧结温度(900,930,950,980,1020℃)对飞机铁基粉末冶金刹车材料材料显微组织、致密化和摩擦磨损性能的影响。

3) friction and wear

摩擦磨损

1.

Effects of Rotating Speed on the Friction and Wear Behavior of Die Cast Magnesium Alloy AZ91D;

转速对压铸镁合金AZ91D摩擦磨损特性的影响

2.

Effect of carbonization on friction and wear properties of C/C-SiC braking materials;

炭化工艺对C/C-SiC制动材料摩擦磨损性能的影响

3.

BP neural network analysis of dry sliding friction and wear of UHMWPE composites;

硅灰石纤维填充超高分子量聚乙烯基复合材料干滑动摩擦磨损的BP神经网络分析

4) wear and friction

摩擦磨损

1.

Effects of Speed and Load on Loading Wear and Friction Resistance of Al_2O_3/Cu Composites;

Al_2O_3/Cu复合材料的载流摩擦磨损性能

2.

Research progress of wear and friction behavior and its mechanism of UHMWPE is introduced.

介绍了超高相对分子质量聚乙烯(UHMWPE)的摩擦磨损特性及其机理的研究进展,重点介绍了改进摩擦磨损性能方法的研究进展,包括交联改性、填料填充改性、增强改性、共混和加工方法的研究等,并针对这些方法的不足之处和可能的新方法提出了今后的研究方向。

3.

Its sliding wear and friction properties were measured by means of a home designed pin on disk apparatus.

选用聚醚醚酮(PEEK)为对象,研究其无润滑条件下的滑动摩擦磨损行为,根据实验测得的有关特性,磨屑形态及试样摩擦面特征,提出了塑性流动磨损机理,解释了实验现象。

5) friction wear

摩擦磨损

1.

Study on friction wear properties of silver matrix brush material;

银基电刷材料的摩擦磨损性能研究

2.

Fabrication and Friction Wear Properties of Steel Shot Reinforced ZA27 Composite;

钢丸增强ZA27复合材料的制备与摩擦磨损特性

3.

Development of WFM reciprocating friction wear testing machine

WFM型往复式摩擦磨损试验机的研制

6) wear

[英][weə(r)] [美][wɛr]

摩擦磨损

1.

The influence of heat treatment on phase structure and wear characteristics of the coating was investigated by DSC,XRD,microhardness measurement and wear tests.

采用超音速火焰喷涂技术在0Cr13Ni5Mo不锈钢基体上制备了铁基非晶涂层,研究了500℃~800℃不同温度热处理对涂层的相组成和摩擦磨损性能的影响。

2.

Wear behavior of both ZQAl9-4 and Ni60A coating on ZQAl9-4 copper substrate under dry-lubricated sliding against GCr15 steel was comparatively investigated with an MM-200 friction and wear tester.

用MM-200型摩擦实验机,对偶采用GCr15钢环,对比考察了ZQAl9-4和其表面Ni60A渗层在干滑动摩擦状态下的摩擦磨损性能以及摩擦热对对偶钢的影响。

3.

In order to study wear automatic restoration action of nanometer MgO/SiO_2 and the influence of frictional condition on automatic restoration,repairing action of nanometer MgO/SiO_2 to worn steel surface as an ad- dtive in 350SN oil is evaluated by using HQ-1 wear machine,and the influence of load,slide velocity and time on its au- tomatic restoration capability is also studied.

为研究MgO/SiO_2复合纳米的磨损自修复作用及摩擦条件对修复的影响,将MgO/SiO_2复合纳米作为添加剂加入350SN基础油中,在HQ-1环块摩擦磨损试验机上考察了MgO/SiO_2复合纳米对磨损表面的修复作用,在不同的载荷、转速、修复时间条件下进行了修复试验,并探讨了摩擦条件对纳米MgO/SiO_2自修复性能的影响机理。

补充资料:摩擦学:表面疲劳磨损

表面疲劳磨损

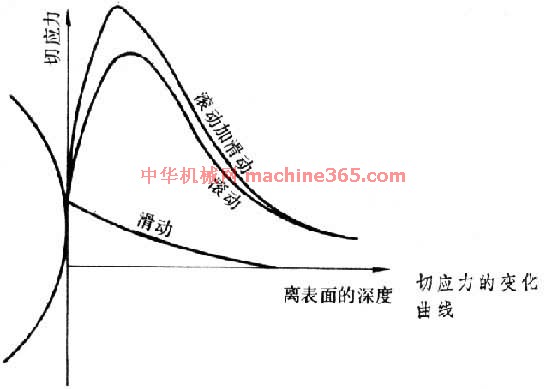

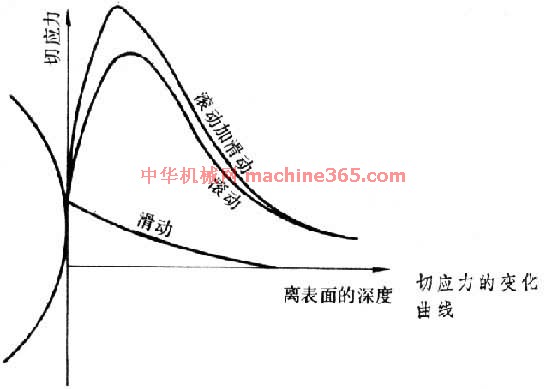

由於循环接触应力的作用﹐在摩擦副工作表面或表层内部形成裂纹并扩展使表层材料剥落的一种磨损。接触运动有滚动﹑滑动或滚动加滑动 3种情况。表面疲劳磨损常发生在滚动轴承﹑齿轮以及钢轨与轮箍的接触面上。不论是点接触还是线接触﹐最大压应力都发生在零件的接触表面上﹐最大切应力则发生在表层内部离表面一定深度处。滚动接触时﹐在循环切应力影响下﹐裂纹容易从表层形成﹐并扩展到表面而使材料剥落﹐在零件表面形成麻点状凹坑﹐造成疲劳磨损。若伴有滑动接触﹐破坏的位置逐渐移近表面(见图 切应力的变化曲线 )。由於材料不可能完全均匀﹐零件表面也不是完全平滑﹐材料有表面缺陷﹑夹杂物﹑孔隙﹑微裂纹和硬质点等原因﹐疲劳破坏的位置往往有所改变﹐裂纹有时从表面开始﹐有时从表层内开始。与表面连通的疲劳裂纹还会受到润滑油的楔入作用﹐使其加速扩展。减少表面疲劳磨损的措施首先在於提高材料的纯洁度﹐如限制非金属夹杂物的含量﹐规定基体组织和碳化物的均匀性等。表面应儘量光洁﹐避免刀痕式磨痕。在可能条件下﹐採取如渗碳和渗氮等表面强化工艺﹐以提高硬度。强化层必须有足够的厚度﹐心部要有足够的强度﹐并选用合适的润滑剂。这些措施都能减小表面疲劳磨损。

)。由於材料不可能完全均匀﹐零件表面也不是完全平滑﹐材料有表面缺陷﹑夹杂物﹑孔隙﹑微裂纹和硬质点等原因﹐疲劳破坏的位置往往有所改变﹐裂纹有时从表面开始﹐有时从表层内开始。与表面连通的疲劳裂纹还会受到润滑油的楔入作用﹐使其加速扩展。减少表面疲劳磨损的措施首先在於提高材料的纯洁度﹐如限制非金属夹杂物的含量﹐规定基体组织和碳化物的均匀性等。表面应儘量光洁﹐避免刀痕式磨痕。在可能条件下﹐採取如渗碳和渗氮等表面强化工艺﹐以提高硬度。强化层必须有足够的厚度﹐心部要有足够的强度﹐并选用合适的润滑剂。这些措施都能减小表面疲劳磨损。

由於循环接触应力的作用﹐在摩擦副工作表面或表层内部形成裂纹并扩展使表层材料剥落的一种磨损。接触运动有滚动﹑滑动或滚动加滑动 3种情况。表面疲劳磨损常发生在滚动轴承﹑齿轮以及钢轨与轮箍的接触面上。不论是点接触还是线接触﹐最大压应力都发生在零件的接触表面上﹐最大切应力则发生在表层内部离表面一定深度处。滚动接触时﹐在循环切应力影响下﹐裂纹容易从表层形成﹐并扩展到表面而使材料剥落﹐在零件表面形成麻点状凹坑﹐造成疲劳磨损。若伴有滑动接触﹐破坏的位置逐渐移近表面(见图 切应力的变化曲线

)。由於材料不可能完全均匀﹐零件表面也不是完全平滑﹐材料有表面缺陷﹑夹杂物﹑孔隙﹑微裂纹和硬质点等原因﹐疲劳破坏的位置往往有所改变﹐裂纹有时从表面开始﹐有时从表层内开始。与表面连通的疲劳裂纹还会受到润滑油的楔入作用﹐使其加速扩展。减少表面疲劳磨损的措施首先在於提高材料的纯洁度﹐如限制非金属夹杂物的含量﹐规定基体组织和碳化物的均匀性等。表面应儘量光洁﹐避免刀痕式磨痕。在可能条件下﹐採取如渗碳和渗氮等表面强化工艺﹐以提高硬度。强化层必须有足够的厚度﹐心部要有足够的强度﹐并选用合适的润滑剂。这些措施都能减小表面疲劳磨损。

)。由於材料不可能完全均匀﹐零件表面也不是完全平滑﹐材料有表面缺陷﹑夹杂物﹑孔隙﹑微裂纹和硬质点等原因﹐疲劳破坏的位置往往有所改变﹐裂纹有时从表面开始﹐有时从表层内开始。与表面连通的疲劳裂纹还会受到润滑油的楔入作用﹐使其加速扩展。减少表面疲劳磨损的措施首先在於提高材料的纯洁度﹐如限制非金属夹杂物的含量﹐规定基体组织和碳化物的均匀性等。表面应儘量光洁﹐避免刀痕式磨痕。在可能条件下﹐採取如渗碳和渗氮等表面强化工艺﹐以提高硬度。强化层必须有足够的厚度﹐心部要有足够的强度﹐并选用合适的润滑剂。这些措施都能减小表面疲劳磨损。

说明:补充资料仅用于学习参考,请勿用于其它任何用途。

参考词条